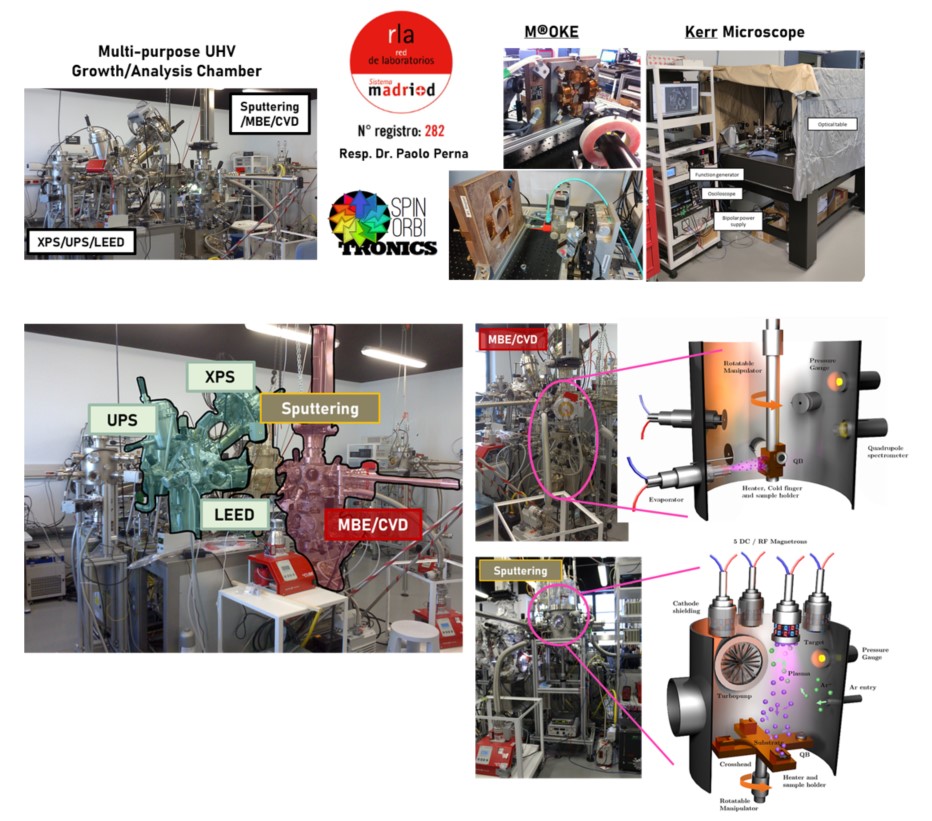

Multi-purpose UHV facility

Multipurpose ultra-high-vacumm (UHV) facility for in-situ growth and characterization with four interconnected chambers:

1. MBE Growth Chamber: Equipped with a manipulator with cooling (LN) and annealing (1200ºC) facilities, and a quartz microbalance implemented in the sample holder. Divided in two stages: one upper stage to grow organic films (3-cell Kentax evaporator for organic materials); this stage is equipped with RGA analyzer and gas dosing facilities that allows CVD graphene growth. The lower stage is equipped with different e-beam and resistive evaporators (a 3-cell Omicron, 4-pocket SPECS, and 3 home-made evaporators) to grow inorganic films.

2. Magnetron Sputtering Chamber: Manipulator with a heating sample holder (500ºC) and a quartz microbalance implemented in the sample holder. It has 5 DC magnetrons for metals and 1 RF magnetron for oxides. It is interconnected to the MBE chamber through a valve and a parking stage.

3. Analysis Chamber: It allows the in situ characterization of thin films growth in the previous chambers with the following techniques:

- X-Ray Photoemission Spectroscopy (XPS) with a monochromated Al K source.

- Ultraviolet Photoemission Spectroscopy (UPS) with He I, HeII and Ne lines.

- Charge compensator (flood gun) to measure insulating materials.

- Low Energy Electron Diffraction (LEED), 3 grids system.

- Cleaning facilities (Ar+ sputter gun), annealing (800ºC) and cooling (LN) manipulator

4. Reactor chamber: In this chamber is possible to dose reactive gases at high doses (maximum pressure of 10-5 mbar), and perform Thermal Desorption Spectroscopy (TDS). Atomic cracker system for H2 and N2.

Advanced Magneto-Optics Lab

The Advanced Magneto-Optics Lab is devoted to the study of magneto-transport properties of thin films and multilayers. It is equipped with:

- Home-made magnetometer setups based on the vectorial magneto-optic Kerr effect (vMOKE) capable of simultaneously perform magnetoresistive (MR), variable temperature (VT) in a wide temperature range (15-500K), and time-resolved Kerr magnetometry/imaging (tr-vMOKE) measurements, in longitudinal/transversal/polar geometries;

- 2 x vectorial Kerr microscopes (EVICO, home-made) allowing for imaging of magnetic domains and simultaneous magneto-transport experiments;

- Set ups enabling magneto-transport and harmonic experiments up to 2T at RT and 9T in 4He-flow cryostat down to 1.7K;

- Vectorial vibrating sample magnetometer (v-VSM) with possibility of applying a maximum magnetic field of 3T

- Computing station equipped with NVIDIA-Titan for micromagnetic simulations.