-

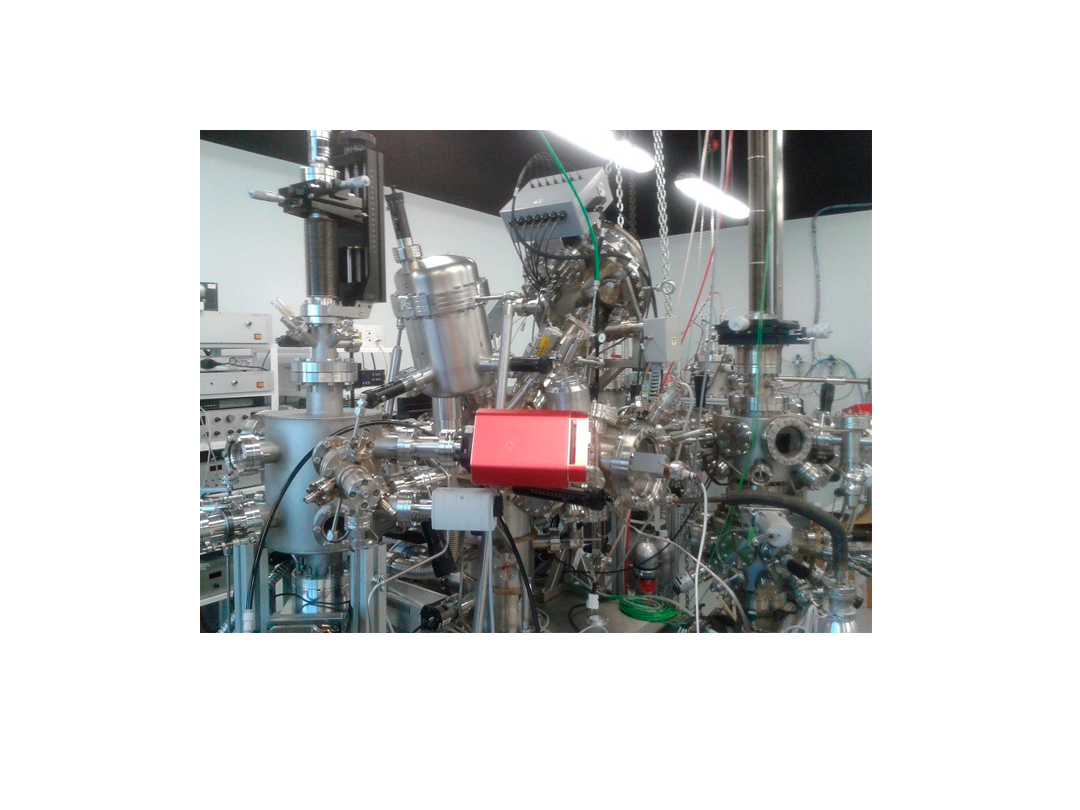

The Molecular Beam Epitaxy (MBE) laboratory is equipped with Ultra High Vacuum systems to perform studies on Surface Physic and Chemistry, and thin film growth. It consist in different independent UHV system, each one with its own fast entry lock, but interconnected in vacuum through a series of valves, in such a way that is possible to transfer samples from one system to other without breaking vacuum.

MBE Growth Chamber: Equipped with a manipulator with cooling (LN) and annealing (1200ºC) facilities, and a quartz microbalance implemented in the sample holder. Divided in two stages: one upper stage to grow organic films (with a 3-cell Kentax evaporator for organic materials); this stage is equipped with RGA analyzer and gas dosing facilities that allows CVD graphene growth. The lower stage is equipped with different e-beam and resistive evaporators (a 3-cell Omicron, and 3 home made evaporators) for metals.

Magnetron Sputtering Chamber: Manipulator with a heating sample holder (500ºC) and a quartz microbalance implemented in the sample holder. It has 5 DC magnetrons for metals and 1 RF magnetron for oxides. It is interconnected to the MBE chamber through a valve and a parking stage.

Analysis Chamber: It allows the in situ characterization of thin films growth in the previous chambers with the following techniques:

- X-Ray Photoemission Spectroscopy (XPS) with a monochromated Al K source.

- Ultraviolet Photoemission Spectroscopy (UPS) with He I, HeII and Ne lines.

- Charge compensator (flood gun) to measure insulating materials.

- Low Energy Electron Diffraction (LEED), 3 grids system

- Cleaning facilities (Ar+ sputter gun), annealing (800ºC) and cooling (LN) manipulator

Reactor chamber: In this chamber is possible to dose reactive gases at high doses (maximum pressure of 10-5 mbar), and perform Thermal Desorption Spectroscopy (TDS). Atomic cracker system for H2 and N2.

We are implementing for a near future:

- An in situ Magneto Optic Kerr Effect (MOKE) set up for magnetic characterization of thin films

- A high pressure cell to perform catalysis experiments at ambient pressure.